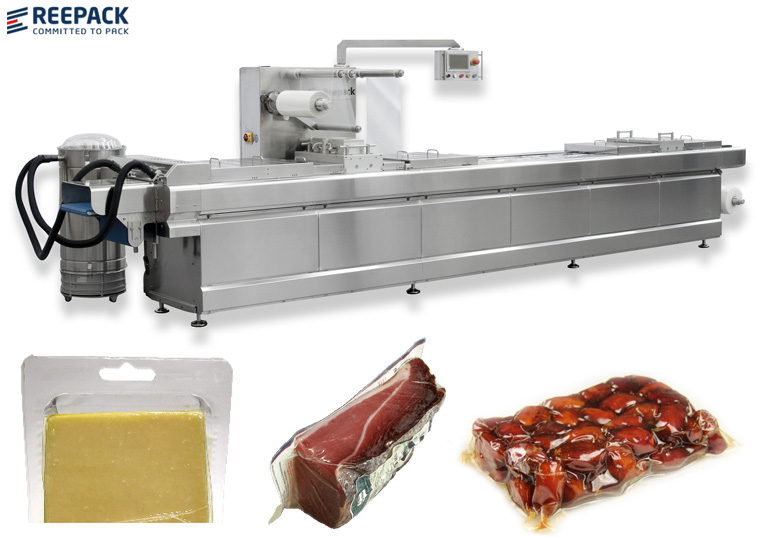

REEFORM T55 Thermoforming Machine

High-performance thermoforming machine

REEFORM T55 Thermoforming Machine, a highly flexible solution designed to cater to a wide variety of modern packaging needs.

Crafted with a robust stainless steel frame, this machine ensures durability and easy maintenance in a hygienic packaging environment. Its open boards allow convenient access to all machine parts, facilitating routine checks and maintenance. The equipment system is efficiently integrated into the machine frame, providing reliable protection against potential damage.

Operating the REEFORM T55 is effortless, thanks to its user-friendly control panel. The interface introduces operators to an intuitive system, enabling easy setting and recording of different programs. With programmable movements, the machine offers maximum flexibility, accommodating diverse formats and products, ensuring versatility for various packaging requirements.

The REEFORM T55 is capable of processing both flexible and rigid film, handling thicknesses of up to 900 microns and film widths of up to 620 mm. This wide range of compatibility allows for modern packaging solutions suitable for various materials.

Its thermoforming capabilities enable trays with a maximum forming depth of 150 mm, and an impressive maximum cut-off length of up to 700 mm, providing ample space for large-sized products.

Machine only need air pressure for Forming and Sealing, Processing Stations are all electric in motion, so that a good saving in energy and little maintenance give a good return of the investment. NOISE FREE

Features:

REEFORM T55 Thermoforming Machine, a highly flexible solution designed to cater to a wide variety of modern packaging needs.

Crafted with a robust stainless steel frame, this machine ensures durability and easy maintenance in a hygienic packaging environment. Its open boards allow convenient access to all machine parts, facilitating routine checks and maintenance. The equipment system is efficiently integrated into the machine frame, providing reliable protection against potential damage.

Operating the REEFORM T55 is effortless, thanks to its user-friendly control panel. The interface introduces operators to an intuitive system, enabling easy setting and recording of different programs. With programmable movements, the machine offers maximum flexibility, accommodating diverse formats and products, ensuring versatility for various packaging requirements.

The REEFORM T55 is capable of processing both flexible and rigid film, handling thicknesses of up to 900 microns and film widths of up to 620 mm. This wide range of compatibility allows for modern packaging solutions suitable for various materials.

Its thermoforming capabilities enable trays with a maximum forming depth of 150 mm, and an impressive maximum cut-off length of up to 700 mm, providing ample space for large-sized products.

Machine only need air pressure for Forming and Sealing, Processing Stations are all electric in motion, so that a good saving in energy and little maintenance give a good return of the investment. NOISE FREE

| Product Code | REEFORM T55 |

| Machine length: | Variable According Configuration |

| Machine width | Variable According Configuration |

| Machine height | Variable According Configuration |

| Cut-off length | up to 700 mm |

| Bottom film | up to 620 mm |

| Product Loading area | Variable According Configuration |

| Free position | Variable According Configuration |

| Thermoforming depth | Max. 150 mm (Parameters may vary according to the film typology and vacuum pumps in use and supplied with the machine.) |

| Machine cycle | From 8 to 12 Cycles / min.. |

| Air pressure | 6 - 10 bar (1000 - 2000 Nl / min.) |

| Power supply | 12 - 22 Kw |

| Water consumption | 80 - 120 L / h - 1,5 - 2,5 bar (18 - 22°C) |

| Weight | 2000 - 3000 Kg |

- REENEXT SOFTWARE

- AIR FREE

- WATER FREE

- NOISE FREE

- STAINLESS STEEL

- USER FRIENDLY

- ECO LINE

- SANITIZING

| Brand | Reepack - Italy |

GET QUOTATION

REEFORM T55 Thermoforming Machine

BARNSLEY UNIVERSAL INC

3 - N302, Jebel Ali Free Zone (North),Dubai, UAE.

+971 58 105 3859 +971 4 883 3306

[email protected]

GET A QUOTE

Tell us about your business requirement, one of our technical expert will be in touch with you soon..!

PROCEED