Raynbow Optical Sorting Machines

Tomatoes Sorting Machine

Potatoes Sorting Machine

Fruits Sorting Machine

Vegetables Sorting Machine

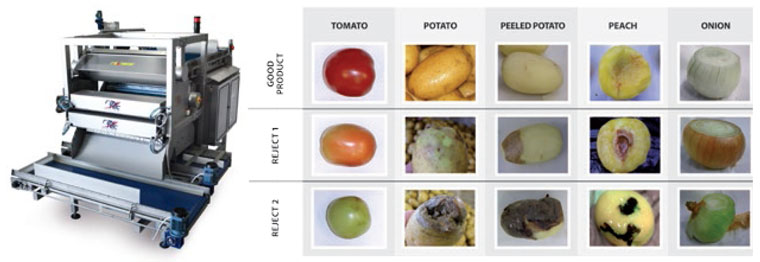

Primarily designed for agro-food products such as fruits and vegetables, Raynbow excels in identifying and eliminating color defects, blemished produce, and foreign objects that may share the same color as the desired product. To ensure comprehensive inspection, the products are carefully placed on a conveyor belt, which prevents them from rolling off. This setup enables thorough examination of all items, and if necessary, they can be promptly ejected when they meet predetermined criteria in both the vision zone and the reject zone.

Raynbow offers a flexible rejection system that can be tailored to specific needs. It can feature either an electro-pneumatic or air activation palette reject system, utilizing electrically controlled ejection valves. Additionally, it can be configured with a single ejection system or operate in 3Way mode, which incorporates two reject systems to distinguish between unusable produce and defects classified as second choice.

- Technology: LED pulsed light with photodiode array

- Optical resolution: 4×4 mm

- Vision: free fall – single / double sides

- Version: 2 WAY / 3 WAY

- Ejection: by fingers / by air nozzles

| Product Code | R-40 | R-50 | R-50 HIGHSPEED | R-70 |

| Capacity | Up to 50 t/h | Up to 70 t/h | Up to 100 t/h | Up to 100 t/h |

| Length of machine (mm) | 2800 | 2800 | 3800 | 2800 |

| Inspection width (mm) | 1000 | 1250 | 1250 | 1750 |

| Inspection belt speed (m/min) | 60-70 | 60-70 | 60-70 | 60-70 |

| Optical resolution (mm) | 4x4 | 4x4 | 4x4 | 4x4 |

| Rejection channel width (mm) | 25 | 25 | 25 | 25 |

- RAYNBOW is a hexa-chromatic machine equipped with NIR (Near InfraRed) technology for Visible Color analysis

- NIR technology can detect the presence of rot and foreign bodies (even if completely black)

- Visible Color analysis allows colour defects to be detected, such as green products, yellowing, etc. In optional mode, the machine can conduct chlorophyll analysis to allow very accurate detection of foreign bodies in products with high chlorophyll content (apples, green beans)

- An ethernet connection is available for remote control

- The machine detects statistical data on rejected products for quality analysis of the selected raw material

APPLICATIONS:

Tomatoes, Cherry tomatoes, Potatoes (unpeeled and peeled), Carrots, Green beans, Onions (unpeeled and peeled), Peppers (whole and cored), Artichokes, Olives, Peaches, Apricots, Cherries, Oranges, Apples, Walnuts (with shells), Strawberries, Pears

BENEFITS:Tomatoes, Cherry tomatoes, Potatoes (unpeeled and peeled), Carrots, Green beans, Onions (unpeeled and peeled), Peppers (whole and cored), Artichokes, Olives, Peaches, Apricots, Cherries, Oranges, Apples, Walnuts (with shells), Strawberries, Pears

- High production capacity. Enables selection of large quantities of product in little time

- Significant labour savings (up to 100% according to application)

- Detection in real time of qualitative and quantitative data of raw material analysed

- Automatic capture of images of rejected products and their filing for post-production analysis

- Constant selection over time, also over 3 work shifts

- Low maintenance costs

- User-friendly for easy use and programming

| Brand | Raytec Vision - Italy |

GET QUOTATION

Raynbow Optical Sorting Machines

BARNSLEY UNIVERSAL INC

3 - N302, Jebel Ali Free Zone (North),Dubai, UAE.

+971 58 105 3859 +971 4 883 3306

[email protected]

GET A QUOTE

Tell us about your business requirement, one of our technical expert will be in touch with you soon..!

PROCEED