Dryce Sorting Machines

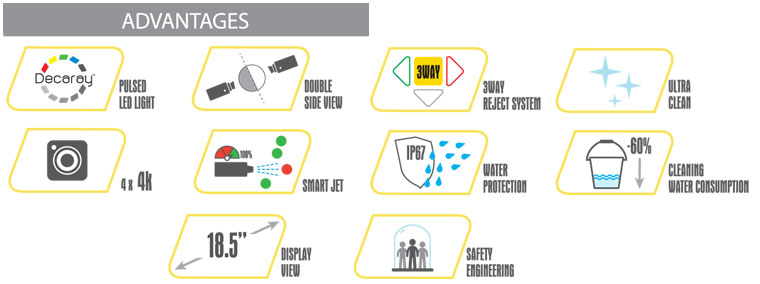

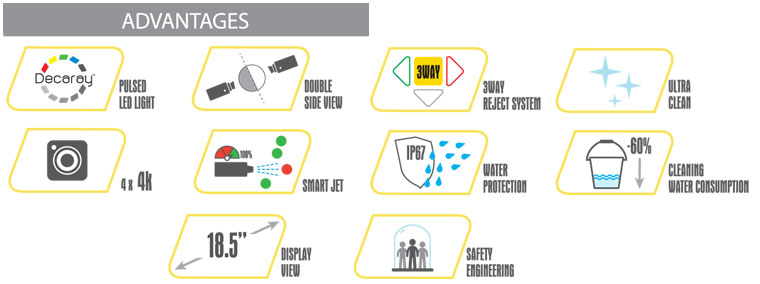

Dryce is an advanced optical sorting machine specifically engineered for the sorting of dry and frozen food products. Equipped with high-resolution cameras, Dryce utilizes the innovative "free fall double side view" system to thoroughly analyze the entire surface of each product, ensuring accurate sorting results.

One of Dryce's key strengths is its ability to effectively eliminate color defects, spoiled produce, and foreign bodies, even if they share the same color as the desired product. To facilitate smooth sorting operations, the machine incorporates a vibratory shaker that efficiently conveys the product to a vertical chute, ensuring a consistent trajectory for precise sorting.

With Dryce, businesses in the food industry can achieve reliable and efficient sorting, enhancing product quality and eliminating potential contaminants from dried and frozen food items.

TECHNOLOGY:

TECHNOLOGY:

One of Dryce's key strengths is its ability to effectively eliminate color defects, spoiled produce, and foreign bodies, even if they share the same color as the desired product. To facilitate smooth sorting operations, the machine incorporates a vibratory shaker that efficiently conveys the product to a vertical chute, ensuring a consistent trajectory for precise sorting.

With Dryce, businesses in the food industry can achieve reliable and efficient sorting, enhancing product quality and eliminating potential contaminants from dried and frozen food items.

- Technology: LED pulsed light with CCD Camera

- Optical resolution: 0.5×0.5 mm

- Vision: on belt – top view

- Version: 2 WAY / 3 WAY

- Ejection: by fingers / by air nozzles

| Product Code | DR-602 | DR-1202 |

| Machine length (mm) | 3,600 | 3,600 |

| Inspection width (mm) | 1,771 | 1,771 |

| Inspection speed (m/min) | 120-240 | 120-240 |

| Optical resolution (mm) | 0.5x0.5 | 0.5x0.5 |

| Air nozzles | 288 | 288 |

- NIR technology can detect the presence of rotten and foreign bodies

- Visible Color analysis allows colour defects to be detected, such as green products, yellowing, etc

- The Chlorophyll analysis allows very accurate detection of foreign bodies in products with high chlorophyll content (peas, green beans)

- Translucency analysis enables detection of stones in the dehydrated fruit and contaminants with a different density from the good product

- The Shape function calculates nine mathematical parameters for each inspected object. Those parameters are representative of geometric characteristics of the object such as eccentricity, compactness or the presence of protuberance

- The Blob function rejects only the groups of pixels (blobs) whose sum of weights is higher than a value defined in the sorting recipe

- The Stem function allows the detection and rejection of stalks, stems, wires or any other thin object in the product stream

- The Glass function enables to detect and reject transparent pieces of glass and plastic

- The Big Stop allows to control the presence of dangerous foreign bodies. This function enables a series of programmable choices: object calculation allocated in three different classes of dangerousness, automatic image capture of dangerous contaminants, alarm generation (with option to stop the machine)

APPLICATIONS:

Frozen eggplant, Frozen corn, Frozen green beans, Frozen peas, Dry tomatoes, Half pears, Frozen okra, Mussels, Sweets, Diced potatoes, Cauliflower rice, Half peaches, Chestnuts, Chewing gum, Frozen potato chips, Frozen Brussels sprouts, Diced onions, Edamame, Frozen red currants, Walnuts, Sugar-coated candies, Pistachios, Frozen spinach cubes, Frozen zucchini, Frozen artichokes

BENEFITS:Frozen eggplant, Frozen corn, Frozen green beans, Frozen peas, Dry tomatoes, Half pears, Frozen okra, Mussels, Sweets, Diced potatoes, Cauliflower rice, Half peaches, Chestnuts, Chewing gum, Frozen potato chips, Frozen Brussels sprouts, Diced onions, Edamame, Frozen red currants, Walnuts, Sugar-coated candies, Pistachios, Frozen spinach cubes, Frozen zucchini, Frozen artichokes

- High production capacity

- Significant labour savings

- Real-time performance analysis

- Automatic capture of images of rejected products

- Constant selection over time

- Low maintenance costs

- User-friendly software

| Brand | Raytec Vision - Italy |

GET QUOTATION

Dryce Sorting Machines

BARNSLEY UNIVERSAL INC

3 - N302, Jebel Ali Free Zone (North),Dubai, UAE.

+971 58 105 3859 +971 4 883 3306

[email protected]

GET A QUOTE

Tell us about your business requirement, one of our technical expert will be in touch with you soon..!

PROCEED