Shipping & Receiving Challenges

Carrier Corrections & Back Charges

Corrections, adjustments, oversize fees, chargebacks. Whatever you call them, UPS and FedEx are hammering you on your small parcel shipments. Those adjustments come directly out of your profit.

Packaging for Long, Odd-shaped SKUs

You ship long, difficult to package products like car parts, rugs, and shovels. You’re getting hit with oversize charges and you need to package your SKUs a better way.

Hard to Scale and Grow

You just went from 100 to 600 orders per day and you can’t keep up. Manual package handling, measuring, and weighing isn’t scalable at your new volumes. To meet demand you’ll need to invest in people or process.

The Cubiscan 210-L Can Help

Eliminate Carrier Back Charges

Declare accurate dimensions and weight on every package, parcel, and carton. Get rework alerts when a package will be flagged for oversize charges. Have documented dimensional proof when working through carrier disputes.

Right-size Your Packaging

Build custom-sized boxes for your larger SKUs by feeding the data directly to a print-on-demand system. Or, feed the data to a cartonization tool to help your packers pick the correct box size to package the order.

Scale With Ease

The Cubiscan 210-L prepares you for future growth. Adding automation to your shipping process speeds up production today and helps meet demand during peak season and times of growth.

How The Cubiscan 210-L is Different

240 Scans/min

Throughput Speed

Real Volume

Data Insights

Open Flap Detection

Detect cartons with open flaps and flag cartons for downstream processes. Such as 1) Partial open, 2) Full open with straight up flaps, and 3) Folded open carton flaps

Carton Damage Inspection

Detect cartons with damage to visible surfaces. Examples include: Crushed corners, Crushed edges/faces, and Large diameter tears and holes (visible to the sensor).

Void Space Calculation

Calculate void space in cartons and totes. Totes produce more reliable results by being able to recognize the familiar pattern/shape of the tote.

For cartons, flaps must be detectable in order to define the outline of the carton and tear it from the measurement.

Get Your Data Where It Needs To Go

Data Integration Options

In-Motion Suite

The Qbit in-motion suite provides the necessary functionality for any in-motion application for host connectivity, labeling, weighing, cubing, scanning, and validation.

Qbit DB

Measurement data is stored in a local or server database on the laptop next to your Cubiscan. The data can be exported as a text file, ODBC, or a push via rest API. Multiple instances of DB can all see the same data.

Typical Receiving & Shipping Workflow

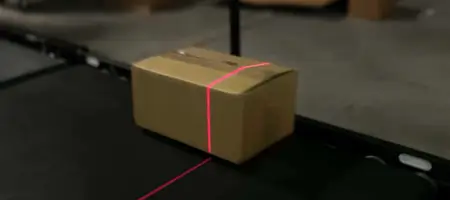

The Cubiscan 210-L can be used to dimension parcels, polybags, flats, and eaches in shipping and receiving applications. Typical operation goes as follows...

Step 1: Scan The Unique Identifier

A fixed scanner or handheld barcode scanner is used to identify the parcel by scanning its license plate or order ID. This can be done in-motion or statically.

Step 2: The Dimensioning Stage

The SKU then runs under the Cubiscan 210-L where it is dimensioned and additional volumetric data is collected.

Step 3: Data Collected & Transferred

Dims and weight are paired with the license plate or order ID using either Qbit IMS or Qbit DB. That data is then pushed to your WMS, ERP, or shipping software.

Step 4: Print/Apply, Verification, Sortation

A shipping label is printed and applied, the label contents verified for accuracy, & the parcel sorted to the correct carrier.

Cubiscan 210-L Availability and Pricing Inquiry

GET A QUOTE

Tell us about your business requirement, one of our technical expert will be in touch with you soon..!