Optimizing Warehouse Logistics with Advanced Material Handling Equipment

In today's fast-paced business environment, optimizing warehouse logistics is crucial for companies seeking to enhance efficiency, reduce costs, and improve overall productivity. One of the key factors in achieving this optimization is the utilization of advanced material handling equipment. With a wide range of products available, such as narrow aisle trucks, forklifts, reach trucks, stackers, tow tractors, pallet trucks, table lifters, scissor lifts, order pickers, drum handling equipment, industrial cleaning equipment, and vacuum lifters, businesses can streamline their operations and create a seamless workflow within their warehouses. In this article, we will explore the benefits and applications of these advanced material handling equipment and shed light on how they can contribute to optimizing warehouse logistics.

Narrow Aisle Trucks:

Narrow aisle trucks are specifically designed to maximize space utilization in warehouses with limited aisle widths. By efficiently navigating narrow aisles, these trucks allow businesses to increase their storage capacity without the need for costly expansion. We will delve into the various types of narrow aisle trucks, their features, and how they improve warehouse logistics.

Forklifts & Reach Trucks:

Forklifts and reach trucks are workhorses in the material handling industry, capable of lifting heavy loads and reaching great heights. We will discuss their versatility, maneuverability, and the role they play in optimizing warehouse logistics by enabling efficient loading, unloading, and stacking of goods.

Stackers & Tow Tractors:

Stackers and tow tractors are indispensable tools when it comes to moving and stacking materials efficiently. We will explore their applications in different warehouse scenarios, highlighting how they contribute to streamlined logistics by facilitating the movement of goods across the warehouse floor and stacking them securely.

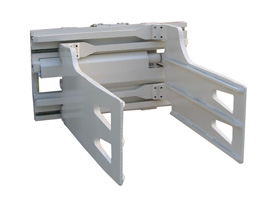

Pallet Trucks & Table Lifters:

Pallet trucks and table lifters are essential for smooth material handling operations within a warehouse. These tools enable easy transportation and positioning of palletized goods, thereby reducing manual labor and expediting the overall workflow. We will discuss their key features, benefits, and the impact they have on warehouse logistics.

Scissor Lifts & Order Pickers:

Scissor lifts and order pickers provide elevated platforms for accessing items at various heights within the warehouse. Their ergonomic design and maneuverability play a significant role in optimizing order picking processes, increasing efficiency, and reducing the risk of accidents. We will explore how these equipment choices contribute to improving warehouse logistics.

Drum Handling Equipment:

Drum handling equipment is specifically designed to handle drums and barrels efficiently. We will examine the different types of drum handling equipment available, including drum lifters, tilters, and dispensing systems. By optimizing drum handling processes, businesses can enhance safety, minimize spills, and improve overall logistics.

Industrial Cleaning Equipment:

Maintaining a clean and safe working environment is paramount in warehouse logistics. Industrial cleaning equipment, such as sweepers and scrubbers, are vital tools in achieving this goal. We will discuss the role of industrial cleaning equipment in warehouse logistics, including the benefits of regular cleaning routines and the impact on employee safety and productivity.

Vacuum Lifters:

Vacuum lifters offer a unique solution for handling heavy and fragile loads without manual intervention. We will explore their applications, advantages, and the positive impact they have on warehouse logistics by reducing the risk of damage and increasing handling efficiency.

In conclusion, advanced material handling equipment plays a pivotal role in optimizing warehouse logistics. The utilization of narrow aisle trucks, forklifts, reach trucks, stackers, tow tractors, pallet trucks, table lifters, scissor lifts, order pickers, drum handling equipment, industrial cleaning equipment, and vacuum lifters allows businesses to streamline their operations, increase efficiency, and reduce costs. By investing in the right equipment and leveraging their capabilities, companies can create a well-organized, productive, and safe warehouse environment, ultimately gaining a competitive edge in the market.

Narrow Aisle Trucks:

Narrow aisle trucks are specifically designed to maximize space utilization in warehouses with limited aisle widths. By efficiently navigating narrow aisles, these trucks allow businesses to increase their storage capacity without the need for costly expansion. We will delve into the various types of narrow aisle trucks, their features, and how they improve warehouse logistics.

Forklifts & Reach Trucks:

Forklifts and reach trucks are workhorses in the material handling industry, capable of lifting heavy loads and reaching great heights. We will discuss their versatility, maneuverability, and the role they play in optimizing warehouse logistics by enabling efficient loading, unloading, and stacking of goods.

Stackers & Tow Tractors:

Stackers and tow tractors are indispensable tools when it comes to moving and stacking materials efficiently. We will explore their applications in different warehouse scenarios, highlighting how they contribute to streamlined logistics by facilitating the movement of goods across the warehouse floor and stacking them securely.

Pallet Trucks & Table Lifters:

Pallet trucks and table lifters are essential for smooth material handling operations within a warehouse. These tools enable easy transportation and positioning of palletized goods, thereby reducing manual labor and expediting the overall workflow. We will discuss their key features, benefits, and the impact they have on warehouse logistics.

Scissor Lifts & Order Pickers:

Scissor lifts and order pickers provide elevated platforms for accessing items at various heights within the warehouse. Their ergonomic design and maneuverability play a significant role in optimizing order picking processes, increasing efficiency, and reducing the risk of accidents. We will explore how these equipment choices contribute to improving warehouse logistics.

Drum Handling Equipment:

Drum handling equipment is specifically designed to handle drums and barrels efficiently. We will examine the different types of drum handling equipment available, including drum lifters, tilters, and dispensing systems. By optimizing drum handling processes, businesses can enhance safety, minimize spills, and improve overall logistics.

Industrial Cleaning Equipment:

Maintaining a clean and safe working environment is paramount in warehouse logistics. Industrial cleaning equipment, such as sweepers and scrubbers, are vital tools in achieving this goal. We will discuss the role of industrial cleaning equipment in warehouse logistics, including the benefits of regular cleaning routines and the impact on employee safety and productivity.

Vacuum Lifters:

Vacuum lifters offer a unique solution for handling heavy and fragile loads without manual intervention. We will explore their applications, advantages, and the positive impact they have on warehouse logistics by reducing the risk of damage and increasing handling efficiency.

In conclusion, advanced material handling equipment plays a pivotal role in optimizing warehouse logistics. The utilization of narrow aisle trucks, forklifts, reach trucks, stackers, tow tractors, pallet trucks, table lifters, scissor lifts, order pickers, drum handling equipment, industrial cleaning equipment, and vacuum lifters allows businesses to streamline their operations, increase efficiency, and reduce costs. By investing in the right equipment and leveraging their capabilities, companies can create a well-organized, productive, and safe warehouse environment, ultimately gaining a competitive edge in the market.

GET A QUOTE

Tell us about your business requirement, one of our technical expert will be in touch with you soon..!

PROCEED